Aerospace and defence

Knoepfel AG is synonymous with multi-layered and high-spec components in a wide variety of materials for the aerospace industry and the defence sector.

As an experienced and competent project partner for the aerospace industry, we offer optimal manufacturing strategies for the complex machining of high-performance materials. To ensure compliance with strict quality specifications, we operate a fully automated 3D measuring centre featuring 100% testing facilities and test reports in a specially air-conditioned clean room. We hold the EN 9100 certification for aerospace and are a member of the Swiss Aerospace Cluster.

Helicopters

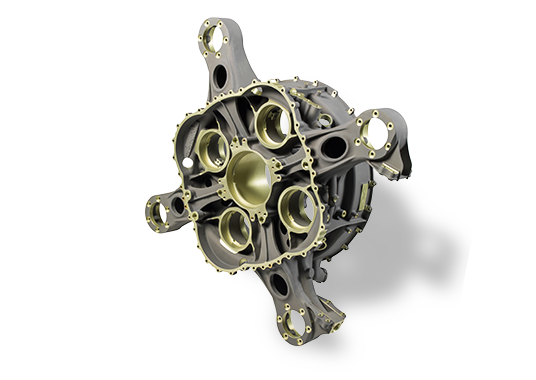

We manufacture complete components and assemblies for helicopters, including heat and surface treatments, superfinishing (roller burnishing and smoothing) and organise all the necessary quality tests. We have particular experience with components such as gearbox housings (main and tail rotor), fixed and rotating rotor masts, carriers and rotor control systems.

References: Kopter Group

Aircraft

In aircraft construction, we have longstanding expertise in the machining of all aerospace-specific materials such as aluminium, titanium, high-alloy steels or special materials. You can count on our many years of experience, especially with regard to gearbox housings for engines or structural components.

References: Saab, Ruag, GE Aviation

Space flight

We make available specific know-how in project handling and process control in the high-end space travel sector. Rely on our expertise and experience in this cutting-edge industry. For example, for the following components and manufacturing services: machining of aluminium forgings with a silicon carbide content of more than 30% for satellites or blades and vanes.

References: Ruag, Synopta

Defence

In the defence sector, we manufacture sophisticated components for defence and defence technology. For such applications, the challenge resides in the combination of machining challenging material alloys, strict compliance with specified standards and special surface processes.

References: Ruag MRO, GDELS, GE Aviation